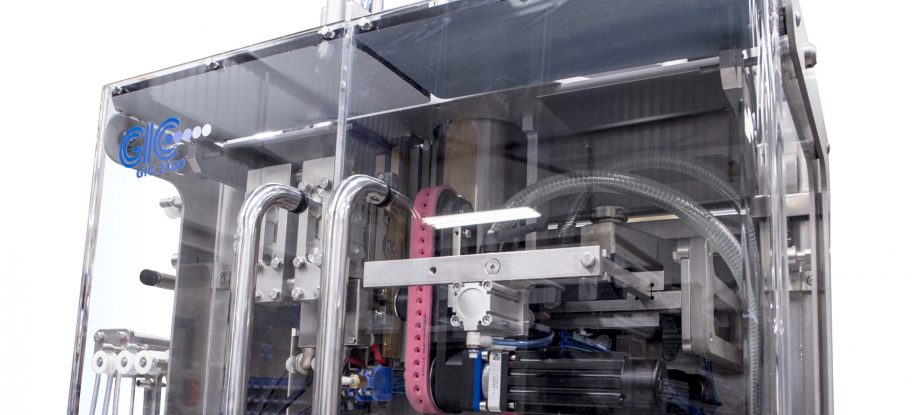

Inverter controlled belt transport system | Pneumatically operated horizontal seal jaws | PLC Control system | Horizontal jaw obstruction detector | Allen Bradley HMI touch-screen | Three seperate heater controllers | Reel run out sensor | Handwheel adjustment for quick tracking of wrapping material

Finished bag take-away elavator sealing jaws | Stainless steel and black hard anodised aluminium construction | Full stainless steel construction | Polyethylene sealing system (impulse welding) | Gas flushing | Static eliminator | Bag shaker | Deflator unit | Servo motor driven transport and horizontal | Overprinter | Selectable multi-pull transport cycles | Adjustable pack support | Feed Systems (dependent on application) | Print Registration unit

The GIC 2100 has been used in the following applications.

Fresh & Frozen Produce | Snacks & Confectionery | Industrial Hardware | Pulses & Powders | Liquids | Bag Styles

Pillow | Gusset | Block Bottom | Euroslot | Punch Hole | Easy Open / Reclose with zip | Quadpack

Augers | Linear weighers | Multi-head weighers | Counters | Volumetric fillers | Liquid pumps | Bucket elevators

Weight: 800kg

Maximum Pack Sizes: 250mm W x 400mm L

Maximum Speed: 90 packs per min

Power Supply: 415V 3-phase 3kW (4kW for servo option)

Compressed Air: Free air – 0.27 cubic mtrs/min (0.06 cubic mtrs/min for servo option) dependent on speed and application

Finish: Black hard anodised aluminium and painted mild steel

Packaging Materials: All suitable heat sealable materials including laminates and polyethylenes (optional impulse sealing)

Reel Outer Diameter: 450mm

Reel Core Diameter: 76mm